The Technology Transfer Office (TTO) at Masaryk University has recently approved the first “Tested in Antarctica” trademarks. These are designed for products that were used on the latest expedition to the university’s J. G. Mendel research station on James Ross Island near the Antarctic Peninsula.

The trademark was approved for boots made by Prabos plus a.s. and for thermal underwear by VÚB a.s. “It’s not always testing in the scientific meaning of the word. It can also mean that the product was tried and tested by the members of the research expedition in demanding polar conditions. The test results are then evaluated by the TTO so that the final decision does not rest with the testers,” says Jana Daňková, TTO business manager, about the decision-making process.

The information about how a specific product was tested and what the trademark means is publicly available at testovanovantarktide.cz. “You can see when and how the product was tested and with what results, who did the testing and if there are any recommendations for the manufacturer or the user,” explains Daňková.

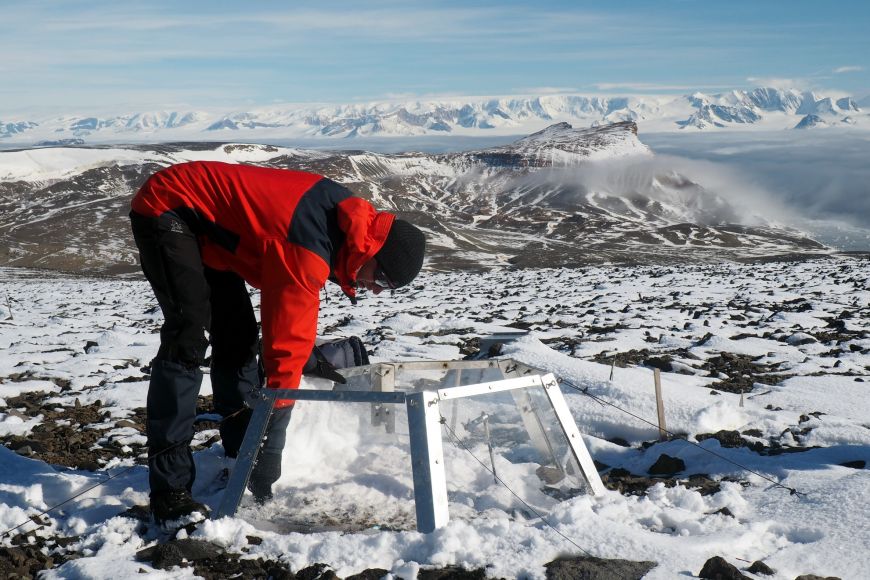

During the expeditions to the J. G. Mendel station, local temperatures are usually between minus and plus 15°C with strong winds. The expedition team have to move around in the snow, walk on icebergs, and wade through flooded streams in difficult terrains. The strain placed on the tested products during the expedition is therefore much greater than it would be on a normal hiking trip.

The scientists, who go to Antarctica to collect and evaluate data for their research, can also evaluate the products they test. Their notes are designed to help the manufacturer improve the product: for example, one of the recommendations for the boots that were tested was to make them in another size.

As the polar researchers already know, the manufacturers greatly appreciate the feedback. Testing in Antarctica has already helped improve the structure of a wind plant due to the local conditions: strong gusts of wind with frequent changes of speed and direction, which bring with them a large amount of sand, small stones, and sea salt. The temperature also changes quickly and the whole continent is exposed to strong UV radiation due to an ozone anomaly.

Based on inquiries from some of the companies, Masaryk University registered the European “Tested in Antarctica” trademark, in addition to the Czech one, in March of this year.